Rubber ceramic liners: When damping force and substantial resistance meet

As some heavy-duty applications call for more durable coatings than standard alumina ones, you may consider getting these products from Chemshun Ceramics. The following lineup comprises rubber ceramic wear liners that combine the best of both worlds. In other words, they offer resistance benefits of the ceramic material and superior impact strength of rubber. Such a unique mix makes them indispensable for uses where abrasive media and shock effects are common.

Our rubber-backed ceramic liners are available in many shapes, including squares, cylinders, plates, hexagonal tiles, etc. They differ in alumina content as well as toughness characteristics, not to mention sizes and other technical specifications. Read them carefully to find the most suitable option for your needs.

To ensure the desired performance of rubber ceramic liners, we put a premium on molecular bonding. It’s a crucial step in the range of production and quality control processes at Chemshun Ceramics. The bond between the materials is necessary to make sure they complement each other. And when it’s at the highest level, you can expect the perfect blend of rubber and ceramic features, such as:

· high mechanical and chemical resistance

· unparalleled shock-absorbing properties

· thermal protection

· vibration and noise reduction

· anti-wear protection

Safeguard your equipment with the right rubber ceramic liner

Reinforced protective properties of these liners are of use for high-impact applications across a myriad of industries. Plus, they can improve the safety of working environments by dampening vibrations and minimizing noise-related hazards. That is why they can help ensure compliance with some occupational regulations.

More specifically, our rubber ceramic wear liners can be utilized in:

· industrial feeders

· conveyor systems

· chutes

· pulley shells

· transfer points

· bunkers

This list is not complete as our liners are suitable for almost all equipment components that are subject to excess wear and tear. For specific uses, you’re welcome to request custom designs, shapes, or sizes. At Chemshun Ceramics, we’re always ready to produce lining solutions that will fit your machinery best.

Worldwide shipping and on-site installation

We can export our rubber-backed ceramic liners and other products to any country. If you want to get more details on the shipping process or the lining material you’re interested in, you can contact us at your convenience.

To avoid installation issues and possible downtime, count on our technicians who will make sure everything works like a charm. Our on-site installation service can save you the bother!

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China

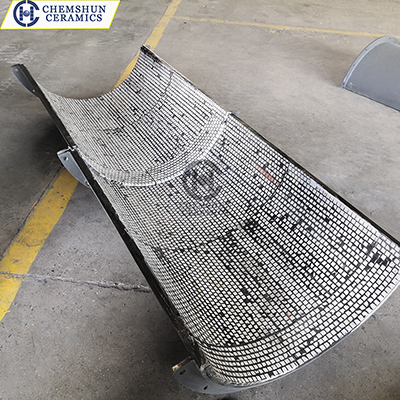

AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Ceramic Rubber Composite Liner

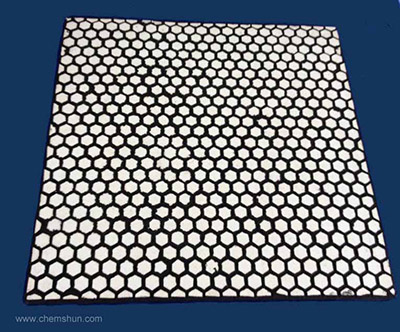

Ceramic Rubber Composite Liner Hex Rubber Ceramic Wear Plate

Hex Rubber Ceramic Wear Plate Pulley Lagging Ceramics

Pulley Lagging Ceramics Square Ceramic Rubber Component

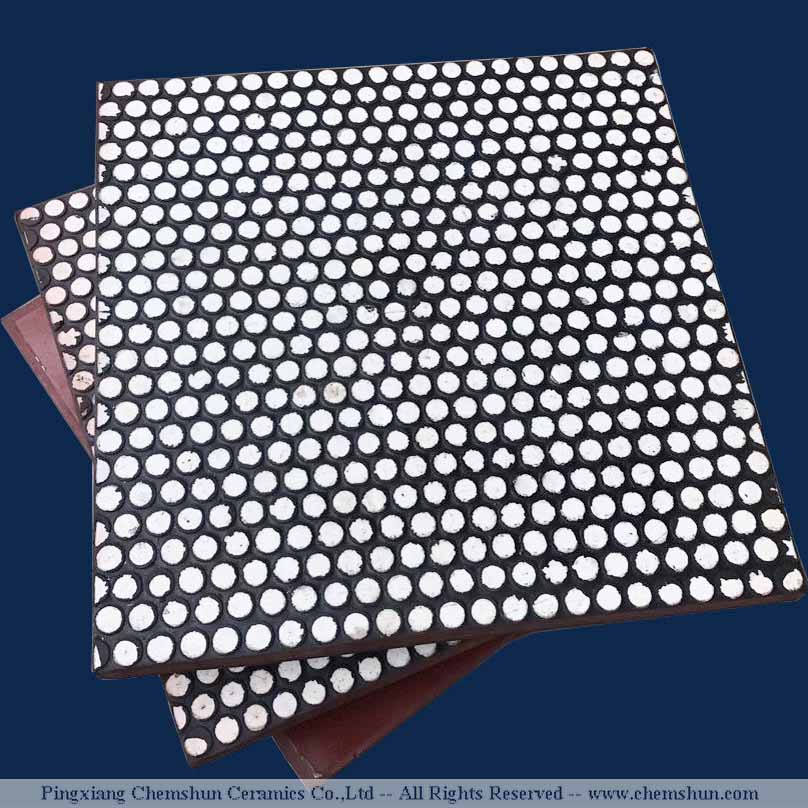

Square Ceramic Rubber Component Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Rubber backed alumina ceramic tiles

Rubber backed alumina ceramic tiles Rubber Ceramic Chute

Rubber Ceramic Chute Wear Resistant Ceramic Rubber Pipe Plate

Wear Resistant Ceramic Rubber Pipe Plate